3D Printing Phoenix is a new technology that uses computers to print objects. It starts with a digital 3D design file, which is then sliced into thin layers that are sent to the printer. The process varies by printer, but all 3D printers use the same basic technology.

The most common type of material used in 3D printing is plastic. Some examples include PLA, which is made from renewable resources, and ABS, which is commonly used in toys and Lego bricks.

3D printing is a cost-effective manufacturing technique that can make prototypes of products quickly and inexpensively. The technology has a number of applications, including making medical devices, prosthetics, and dental parts. It also allows companies to test new designs and get their product on the market faster than traditional manufacturing methods. 3D printers can use a wide variety of materials, from plastics to metals. However, the quality of the finished product varies with the type of material used and the fabrication method.

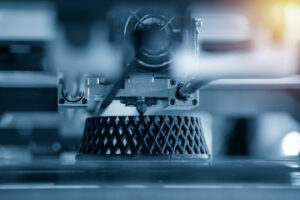

The most common 3D printing technologies include fused deposition modeling, stereolithography, and selective laser sintering. These processes use a heated nozzle to print thermoplastic polymers in layers, building the product layer by layer. These layers are then bonded together to form the final part. These printing techniques are available in a range of prices, from inexpensive to high-end. However, before investing in a 3D printer, you should consider the initial purchase costs as well as ongoing purchases and maintenance costs.

There are a number of ways to reduce the cost of 3D printing, including choosing the right materials. Some materials are cheaper than others and may be suitable for specific applications. For example, you can use a cheaper plastic for prototyping or visualizing the design, while more expensive metals may be necessary for production-grade parts.

Another way to reduce the cost of 3D printing is by using post-processing techniques. These techniques can remove sagging or warping from the printed part and give it a polished finish. They can also improve the appearance of a product by adding different colors. These techniques are common for thermoplastics and some resins.

In addition to reducing the cost of manufacturing, 3D printing can also help lower energy demands by shortening manufacturing times and reducing shipping distances. These efficiencies can significantly cut CO2 emissions, especially in industrial settings.

Another benefit of 3D printing is its ability to create complex geometries that are impossible or impractical for traditional manufacturing processes. This flexibility makes it an ideal tool for a number of industries. However, it is important to keep in mind that there are still a few barriers to the adoption of this technology. For one, many companies are unfamiliar with it and may not understand how it works.

Rapid Prototyping

3D printing can drastically reduce the time it takes to turn a design into a product prototype. Traditional prototyping methods like CNC machining or injection molding require expensive tools and molds that can take weeks to make, but 3D printing allows you to print your own prototypes without these costly equipment costs. This helps speed up your project timeline and allows you to test multiple iterations of your product quickly and efficiently.

The 3D printing process works by building a physical model using three-dimensional computer-aided design (CAD) data. The printer adds layers of material to the printed object, which gives it its structural integrity. This makes it a great choice for rapid prototyping, which is an important step in the engineering design process.

In this stage, engineers are often trying to prove their ideas and validate their designs with a proof of concept (PoC) prototype. A PoC can demonstrate a product’s viability, ergonomics, and user experience and can help determine whether the design will meet the necessary functional requirements for a preproduction prototype. A PoC can also be used to test the performance and strength of a design.

Rapid prototyping is a vital step in the development of any product, and it helps ensure that a finished product will function as intended. However, getting a functional and reliable prototype is not as simple as uploading a CAD file to your 3D printer and pressing “print.” If you’ve ever tried to print a 3D object only to find that it failed, it may have been due to incorrect settings or errors in the design. This could be anything from mesh holes, gaps in the material’s surface, or incomplete lines that create support structures.

This is why it’s so important to use a professional service that offers slicing and optimization software, as well as quality assurance and inspection services. A 3D printing service that offers these services can prevent your prototype from failing and save you the hassle of re-printing and reslicing your model.

Xometry’s rapid prototyping service uses a variety of manufacturing technologies to provide an end-to-end solution for your engineering project. Our team of experts can build your prototype using a wide range of materials, including plastics, metals, and urethane casting. Our wide array of capabilities and fast turnaround times allow you to prototype your design quickly and cost-effectively, and can reduce your design-to-production timeline from months to weeks.

Customizable

A 3D printer builds a physical object from a virtual model on a computer screen using plastics, resins or metals. This process is called additive manufacturing because it adds layers of material rather than removing them. This allows manufacturers to customize products for specific applications and market needs. The customizations can be based on design, dimensions, materials and other features. The customizations also allow for precise and cost-effective prototyping, reducing development time and costs.

Customizable 3D printing is an effective way to make prototypes for industrial and consumer applications, including fashion, automotive, healthcare and aerospace. Many businesses have embraced this technology to improve efficiency and profitability by streamlining the product-development process and enhancing customer experience. For example, BMW offers customized accessories and components for its vehicles that can be matched to the buyer’s individual preferences. In addition, companies such as Shapeways offer online marketplaces for customizable 3D printed products ranging from jewelry and accessories to home decor and tech gadgets.

In order to use a 3D printer, users need a CAD (computer-aided design) program and a model file. There are a variety of programs available, including free web apps such as TinkerCad and AutoCAD. The Digital Media Lab (DML) is equipped with several MakerBot 3D printers and provides workshops for faculty, students and staff on digital design and fabrication.

Compared to traditional methods, 3D printing offers faster and more accurate results. This method can produce complex structures that are impossible to create with casting, molding, forming or machining. It is also more environmentally friendly, as it uses less energy and produces fewer waste materials.

There are a variety of ways to customize your 3D prints, including changing the color and size of the object. These processes are usually done by applying a heat treatment to the object, which changes its material properties. This can also increase the durability of the object.

It is important to understand that the quality of your print depends on the specifications chosen for the print. Choosing the right materials, layer height, printing speed and infill density will affect your print’s overall quality. Your 3D printer service may provide guidance to help you select the best specifications for your print.

Versatile

The versatility of 3D printing enables it to be used in a wide range of applications. While proficiency with computer-aided design is recommended, students, educators and researchers from any discipline can download existing 3D digital models on user-generated websites or capture a real-world object using 3D scanners to cost-efficiently develop and customize components to support their envisioned projects.

Also referred to as additive manufacturing, 3D printing converts a digital 3D model into a solid three-dimensional physical object by adding material layer by layer. This is in contrast to traditional machining, casting and forging processes, which remove material from an existing stock item or pour it into a mold and shape it with tools like dies, presses and hammers.

A wide variety of materials can be used in 3D printing, from plastics to metals to ceramics and composites. The selection of a material depends on the desired application and printability. For example, some materials are biodegradable or soluble in water. Others are able to withstand high temperatures or resist chemicals. Specialized conductive materials enable the fabrication of electrical components and sensor enclosures. And medical and healthcare professionals can use biocompatible materials to produce anatomical models, implants and prosthetics that are safe for prolonged contact with living tissue.

The most common 3D printing techniques are Fused Deposition Modelling (FDM), Stereolithography (SLA) and Selective Laser Sintering (SLS). FDM uses a heated nozzle to extrude thermoplastic filaments on a build platform, while SLA and SLS use a laser to melt and solidify liquid resin or powdered materials.

Each of these printing techniques has its own merits and drawbacks, making them suitable for different types of projects and materials. For example, PLA, or Polylactic Acid, is the most popular plastic filament for FDM printing because of its low melting point, good layer adhesion and dimensional accuracy. This type of plastic is made from renewable, biodegradable materials and can be printed in a range of colors.

For more advanced projects, users can experiment with different soluble and non-soluble materials for the best results. In addition to plastics, a variety of materials for 3D printing include glass, wood, concrete and food. Unlike traditional manufacturing processes, 3D printing is environmentally friendly, producing no waste and requiring little energy.